The demands on materials and production processes in foundry technology are constantly increasing. Cost pressure is forcing rationalization and the economical use of resources. In order to accompany this process, we are constantly developing new ideas which we implement in research projects with various project partners from other research institutes and from industry. Our main areas of research can be divided into

Development of casting alloys with new properties

New casting alloys that meet various property requirements open up new areas of application. This also applies to the modification of alloys already in use. The components to be produced are becoming increasingly complex and require defined properties in various areas. These requirements can be met very economically by casting. Components with different properties in different areas can be produced by modifying a material locally or by combining several materials.

Modeling and simulation

Modeling and simulation are key to understanding complex processes. They facilitate the targeted adjustment of microstructures and properties. They allow energy, time and material costs to be optimized.

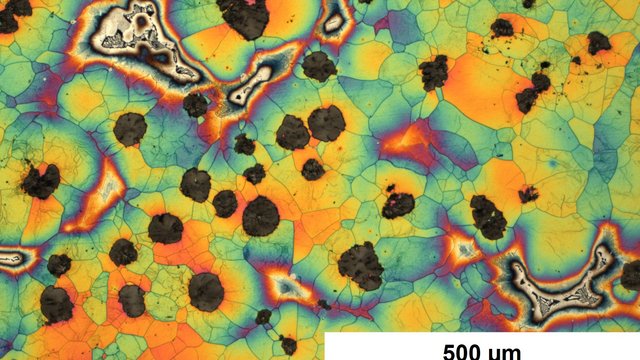

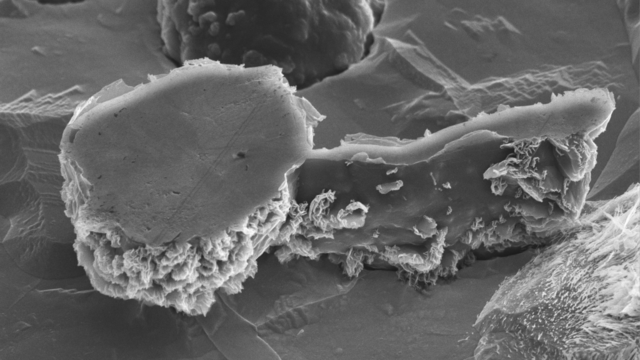

Predicting microstructure and properties

A large number of grain refining, refining and inoculation agents are used in industry today, which produce certain microstructures under very specific conditions. The theoretical basis for this is not yet known, so that targeted further development is not possible. This applies to both ferrous alloys and non-ferrous metals. We therefore want to investigate the processes involved in grain refinement, refining and inoculation with the aim of modeling grain formation and grain growth.

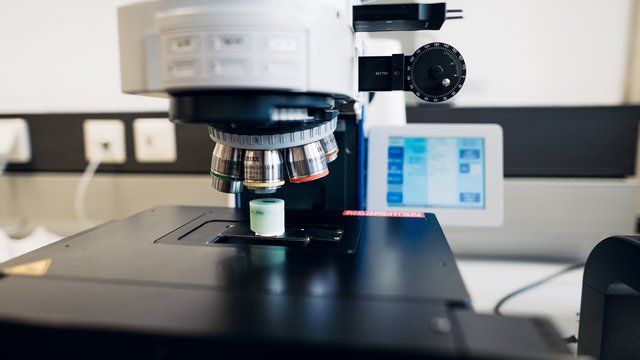

Development and control of processes

The development of new alloys requires an examination of the manufacturing processes. At the same time, appropriate process control must ensure that consistent quality is guaranteed.

Our future research topics on these points deal with

- Gradient casting (combination of different iron casting materials with different properties)

- gradient structures (components made from different materials)

- the micro-alloying of Al-Cu alloys to optimize microstructure and properties

- the hot cracking tendency of AlCuTi alloys in gravity die casting

- melting metallurgical measures for the quality assurance of Al secondary alloys

- the age-hardenable aluminum alloy AlZnMgCu

- the combination of refining the eutectic silicon and refining the primary silicon of Al-Si alloys for engine construction

- Modeling of nucleation and grain growth processes

- Process control of grain refinement and inoculation